PRODUCTS

Product Category

PC+ABS Flame Retardant Thermoplastic Injection Molding Compound 70%PC for Car Door Handle

Item No.:

800-9

Item No.:

800-9

Category:

Summary

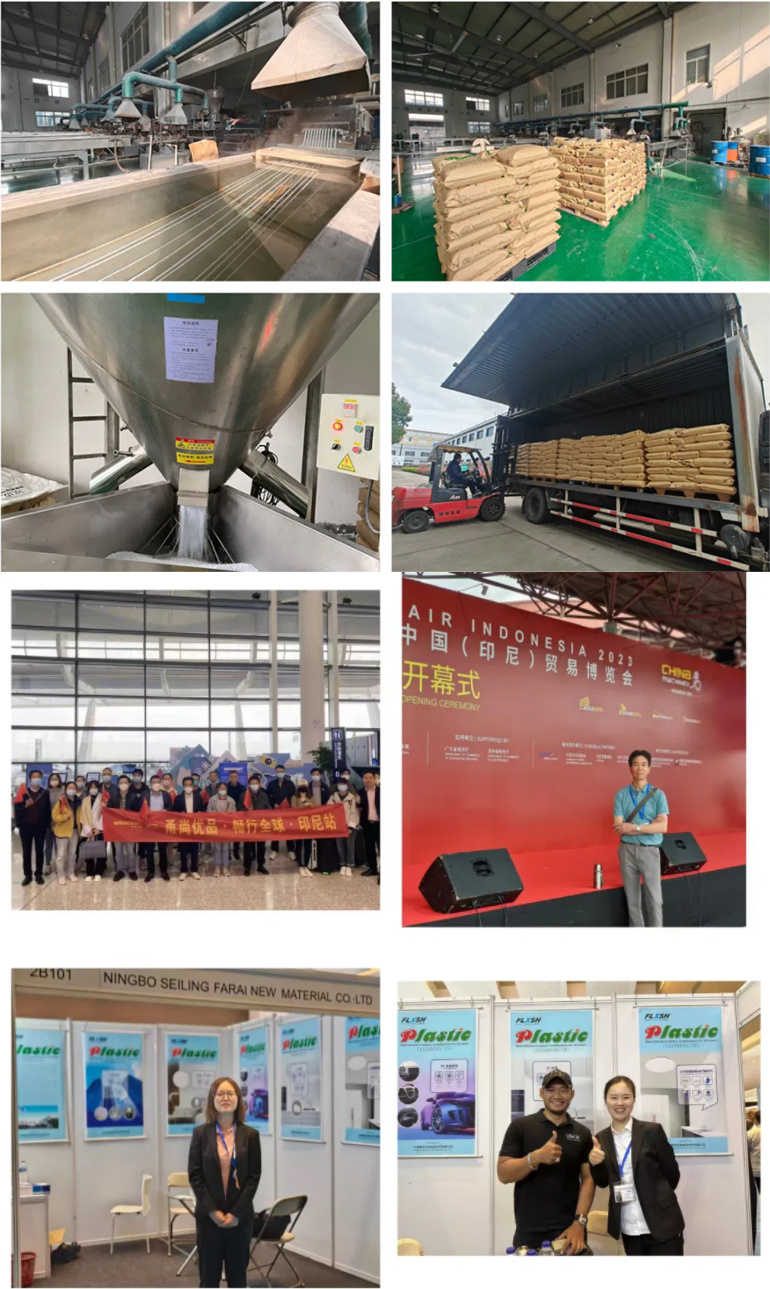

Ningbo Sailing Farai New Material Co., LTD. was founded in 1998. It is a company specializing in the research, development, production and sales of engineering plastics, general-purpose plastics and modified plastics.

Description

There are mainly PC modification, ABS modification, PBT modification, etc., as well as PC alloy series, including PC/ABS alloy, PC/PBT alloy, PC/PET alloy. Modified PC series include (flame retardant, reinforced, anti-aging, antistatic, wear-resistant, etc.) and modified ABS include (flame retardant, heat resistant, high impact, high gloss, etc.) material, PC shading material, PC paint-free, etc.), and has won unanimous praise from customers. The PC flame retardant materials we produce are matched with many well-known domestic enterprises, such as: Bull Group, Delixi Group, Hongyan Electric, Chint Group, Sunshine Group, Ruiming Electric, Haitian Technology, etc., and have long-term cooperation.

In addition, the company's products have been sold all over the world. Our customers come from more than 20 countries such as South Korea, Russia, Bangladesh, Vietnam, Kazakhstan, India, Indonesia, Ghana, Nigeria, South Africa, Egypt, and Saudi Arabia.

| Shipping Cost: | To be negotiated |

| CAS NO: | 24936-68-3 |

| Forrmula: | [-C6h4c(CH3)2c6h4oco2-]N |

| Molecular Principal Chain: | Polycarbonate Ester |

| Samples: | 10 kg Is Free |

| Customization: |

PC ABS composite material Available |

Basic Info.

| Model NO. | 800-9 | Color | Black |

| Colors | Can Be Customized | Price | Object Based Product |

| Physicochemical Property | Customized | Sample | 10 kg Is Free |

| Delivery Date | 3-7day | Application | Sockets, Switches, Cell Phone Chargers, Communicat |

| Transport Package | Environmental Protection Woven Bag | Specification | 25kg/Bag |

| Trademark | FLXSH | Origin | China |

| HS Code | 3907400000 | Production Capacity | 20000tons/Year |

Packaging & Delivery

| Package size per unit product | 50.00cm * 70.00cm * 100.00cm |

| Gross weight per unit product | 25.000k |

Product Description

WHAT IS A PC/ABS RESIN MATERIAL BLEND?

PC/ABS (polycarbonate / acrylonitrile-butadiene-styrene terpolymer blend) is a thermoplastic alloy of (PC) polycarbonate and (ABS) acrylonitrile-butadiene-styrene. Both PC/ABS materials are well known amorphous plastics. Alloying these two materials enhances processability, and provides non-halo flame retardancy.

Polycarbonate (PC) is a rigid thermoplastic that provides clarity, toughness, and good heat resistance. By itself, polycarbonate has reasonable resistance to burning, and that resistance increases by adding flame retardants that are typically halogen-containing. Acrylonitrile-butadiene-styrene is a well know rigid thermoplastic that offers both moderate impact and moderate chemical resistance. The heat resistance of acrylonitrile-butadiene-styrene is lower than that of polycarbonate. Like polycarbonate, halogen containing additives are used to increase resistance to burning.

Most polymers tend to undergo a decrease in viscosity as shear rates increase. That behavior allows modest increases in injection pressure to help fill injection molded parts. Since polycarbonate very gradually decreases in viscosity as shear rates increase, it can be a challenge to process. While ABS is used in many applications, the usefulness of ABS is limited by medium heat resistance, and by medium impact performance. Flame retardant grades of both PC and ABS primarily use "halogen FR technology," and use of that technology can limit applications. These limitations can be overcome by using compounding technology to produce PC/ABS alloys.

Unlike PC, alloys of PC and ABS do undergo a significant decrease in viscosity as shear rates are increased. This allows PC ABS resin to be processed more easily than pure PC. PC ABS materials are very tough materials. Although they are not as tough as PC alone, they are much tougher than ABS. They also have much higher heat resistance than pure ABS. A "non-halogen" flame retardant technology is used in FR PC/ABS blends. This expands the applications for this tough, moderate heat resistant material.

Although Polymer Resources offers PC/ABS blends in a wide range of melt flows, we are always willing to produce products within a 5 unit sub-range to suit a customer's specific needs.

Additives, Modifiers, and Reinforcing Agents:

- Additives - UV stability, easy release (mold releases), colorants, and other stability additives

- Modifiers - Flame retardants, impact modifiers, flow enhancers

- Reinforcing Agents - Glass fibers, mineral fillers

Technical Data Sheet

| Item | PC/ABS | 800 | |||||

| Product characteristics | Flame retardant V2,Anti-UV | Method of processing : Injection molding | |||||

| Test Environment:Constant temperature and humidity | |||||||

| NO. | Proofing Courses | Test Conditions | Test Standards | Units | Test Results | ||

| 1 | Melt Index | 300ºC,1.2kg | ASTM D-1238 | g/10min | 10 | ||

| 2 | Density | / | ASTM D-792 | g/cm3 | 1.2 | ||

| 3 | Mold Shrinkage | 150×100×3.2mm | ASTM D-955 | % | 0.5-0.7 | ||

| 4 | Tensile Strength | 50mm/min | ASTM-D-638 | Mpa | 66 | ||

| 5 | Breaking Elongation | 50mm/min | ASTM-D-638 | % | 180 | ||

| 6 | Flexural Strength | 2mm/min | ASTM-D-790 | Mpa | 96 | ||

| 7 | Flexural Modulus | 2mm/min | ASTM-D-790 | Mpa | 2654 | ||

| 8 | IZOD Impact strengthnotched | 23ºC,3.2mm | ASTM-D-256 | J/M | 880 | ||

| 9 | HDT | @1.82MPA | ASTM-648 | ºC | 129 | ||

| 10 | Ball pressure | 125ºC | GB/T5169-21 | S | ≤1.8mm | ||

Related Products

Product Application

Online Message

Thank you for your attention to us. If you have any needs or comments, please leave us a message.