PRODUCTS

Product Category

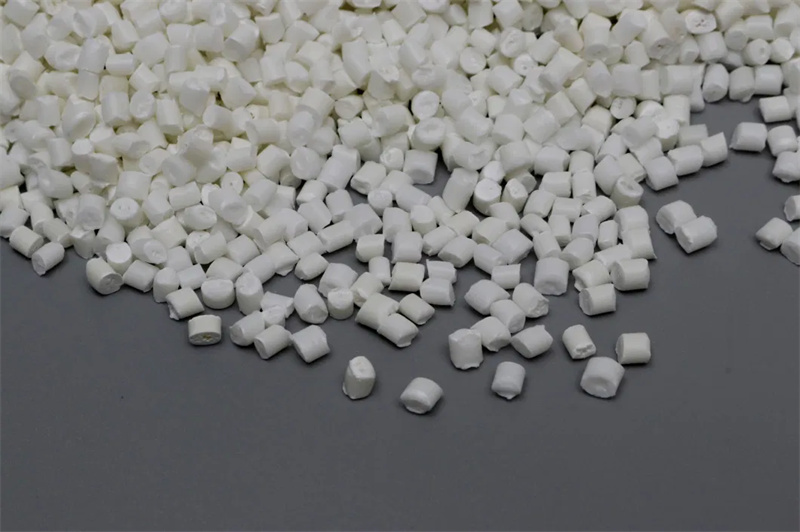

PP High Temperature Resistance Modifed Engineer Plastic Polypropylene for Motorcycle

Item No.:

E-011

Item No.:

FLX-101

Category:

Summary

Ningbo Sailing Farai New Material Co., LTD. was founded in 1998. It is a company specializing in the research, development, production and sales of engineering plastics, general-purpose plastics and modified plastics.

Description

There are mainly PC modification, ABS modification, PBT modification, etc., as well as PC alloy series, including PC/ABS alloy, PC/PBT alloy, PC/PET alloy. Modified PC series include (flame retardant, reinforced, anti-aging, antistatic, wear-resistant, etc.) and modified ABS include (flame retardant, heat resistant, high impact, high gloss, etc.) material, PC shading material, PC paint-free, etc.), and has won unanimous praise from customers. The PC flame retardant materials we produce are matched with many well-known domestic enterprises, such as: Bull Group, Delixi Group, Hongyan Electric, Chint Group, Sunshine Group, Ruiming Electric, Haitian Technology, etc., and have long-term cooperation.

In addition, the company's products have been sold all over the world. Our customers come from more than 20 countries such as South Korea, Russia, Bangladesh, Vietnam, Kazakhstan, India, Indonesia, Ghana, Nigeria, South Africa, Egypt, and Saudi Arabia.

Basic Info.

| Model NO. | FLX-101 | High Temperature | 125 |

| Glass Fiber Content | 20% 30% 40% | Flame Retardant Class | V0 V1 V2 Hb |

| Impact Strength | High | Mfi | Adjustable |

| Long/Short Glass Fiber | Both Have | Factory or Trade Company | Modified Plastic Factory |

| Colors | Customized Color | Delivery | 3-7 Days |

| Sample | Free | Process | Injection Molding |

| Application | Auto Parts | Transport Package | Environmental Protection Woven Bag |

| Specification | 25kg/Bag | Trademark | FLXSH |

| Origin | China | HS Code | 3902100090 |

| Production Capacity | 20000tons/Year | ||

Packaging & Delivery

|

Package Size |

80.00cm * 45.00cm * 12.00cm |

|

Package Gross Weight |

25.000kg |

Product Description

PP (Polypropylene) flame retardant plastic with drop

1.5VA 5VB.Vo.V1.V2.HB can be customized;

2. V0 grade flame retardant 1.6/0.8 mm standard, high fire extinguish:

3. Products comply with UL94 certification;

4 MES system monitors the production process to ensure zero errors in the process;

5. Stable performance and improved product rate by about 10%.

Polypropylene (PP) is a tough, hard crystalline thermoplastic. This straight-chain hydrocarbon resin is the lightest polymer of all commercial plastics. PP can appear as either a homopolymer or a copolymer and can be greatly enhanced with additives.

It finds application in packaging, automotive, consumer good, medical, cast films, etc. Depending on how it is produced and formulated, PP can be:

1 hard or soft,

2 opaque or transparent,

3 light or heavy,

4 insulating or conductive,

5 neat or reinforced with cheap mineral fillers, short or long glass

fibers, natural fibers or even self-reinforced.

|

|

| Item | PP | Model:FLX-101 | |||||

| Product characteristics | Flame retardant | Method of processing : Injection molding | |||||

| Test Environment:Constant temperature and humidity | |||||||

NO. |

Proofing Courses |

Test Conditions |

Test Standards |

Units |

Test Results |

||

| 1 | Melt Index | 300ºC,1.2kg | ASTM D-1238 | g/10min | 15 | ||

| 2 | Density | / | ASTM D-792 | g/cm3 | 0.97 | ||

| 3 | Mold Shrinkage | 150×100×3.2mm | ASTM D-955 | % | 1.2-1.4 | ||

| 4 | Tensile Strength | 50mm/min | ASTM-D-638 | Mpa | 26 | ||

| 5 | Breaking Elongation | 50mm/min | ASTM-D-638 | % | 45 | ||

| 6 | Flexural Strength | 2mm/min | ASTM-D-790 | Mpa | 42 | ||

| 7 | Flexural Modulus | 2mm/min | ASTM-D-790 | Mpa | 1300 | ||

| 8 | IZOD Impact strengthnotched | 23ºC,3.2mm | ASTM-D-256 | J/M | 130 | ||

| 9 | HDT | 0.45MPA | ASTM-648 | ºC | 125 | ||

| 10 | Glow Wire Tester | 850ºC |

GB/5169 |

S | ≤30S | ||

| 11 | Ball pressure | 125ºC | GB/T5169-21 | S | ≤2.0mm | ||

| 12 | Flammability | 1.6mm | UL-94 | Class | V0/HB | ||

Related Products

Product Application

Online Message

Thank you for your attention to us. If you have any needs or comments, please leave us a message.